Bruschi die casting BLOG. Stay on top of the Industry

As winner of numerous international awards, Bruschi Spa is known for its innovative approach in design and technology. We are glad to share our insights and experiences with the industry members.

The versatility of zinc alloys can be tested in some sectors more than in others. A sector that offers great creative and design freedom is household appliances: in fact Zamak components for household appliances contribute to make the entire object unique, exclusive and immediately recognizable.

In this article we present some case studies relative to components made of zinc alloys for doors and windows. Zinc alloys are a perfectly suitable material for the production of components for the building industry and, among the various fields of application, doors and windows are certainly a growing industry with interesting developments.

Cost reduction in zinc die casting is an activity that shall be executed without affecting the quality and functionality of the component that is produced. All the activities that aim to increase productivity, to diminish scrap rate and to simplify productive processes, as well as the choices of materials and processing, are cost reduction strategies.

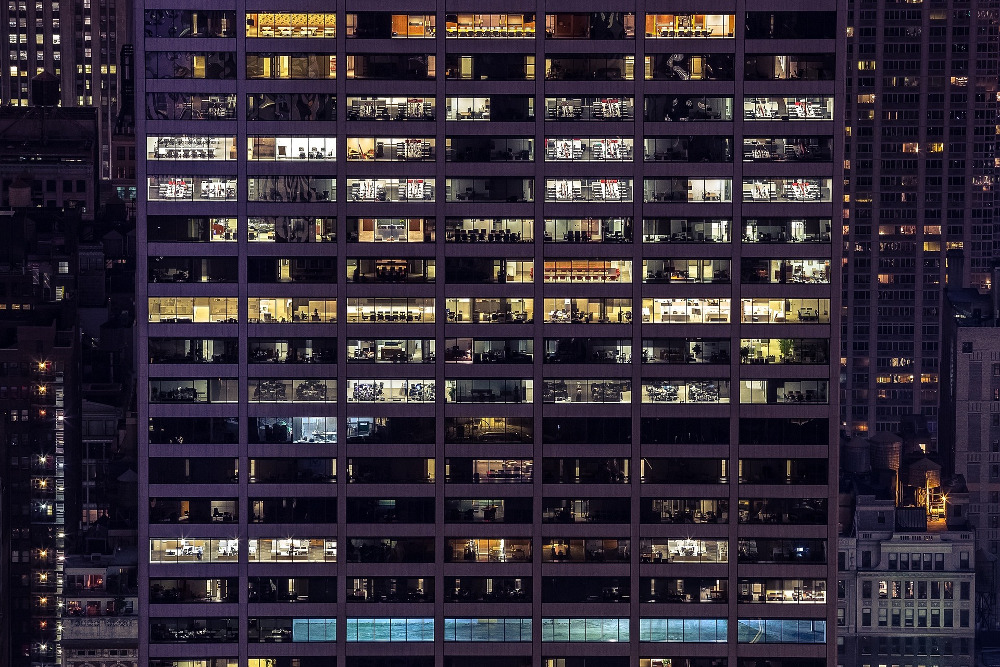

In this article, after briefly depicting the hierarchical structure of the automotive industry and the reference standard for the Tiers of different levels, we analyze the special partnership that exists between a Tier 2 automotive supplier and its customers, specifically examining the relationship of trust that can be established between a Tier 1 and a SME (Small and Medium Enterprises) Tier 2 automotive supplier.

Zinc alloys are a material that, if employed in die casting, allows the achievement of products with thin wall thickness. This property of zinc alloys results in an important added value because it permits the production of components with reduced weight and dimensions, thus benefiting from cost and raw material saving.

Thanks to their excellent mechanical and physical properties zinc alloys are a perfect material for die casting: they are indeed resistant, fluid, durable and rigid. But which are the best zinc alloys for hot chamber die casting? In this post we are going to analyze the different characteristics of zinc alloys for hot chamber die casting in order to define the best choice on the basis of the features that the final product requires.

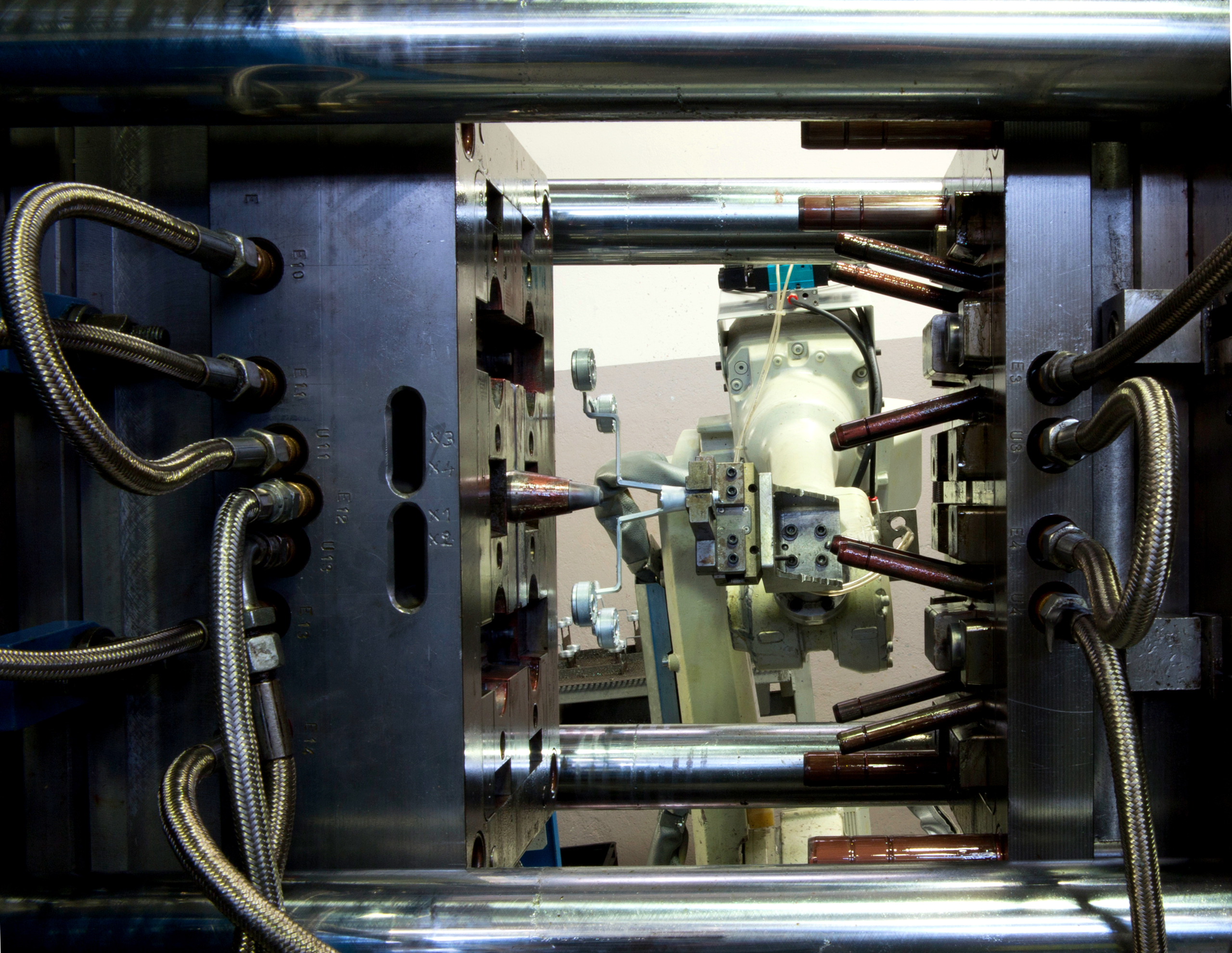

In this post we are going to analyze a case study that explains how to reduce casting defects through mold design. Due to mold wear condition components started to show superficial defects: Bruschi engineers have thus introduced improvements in order to reduce casting defects.

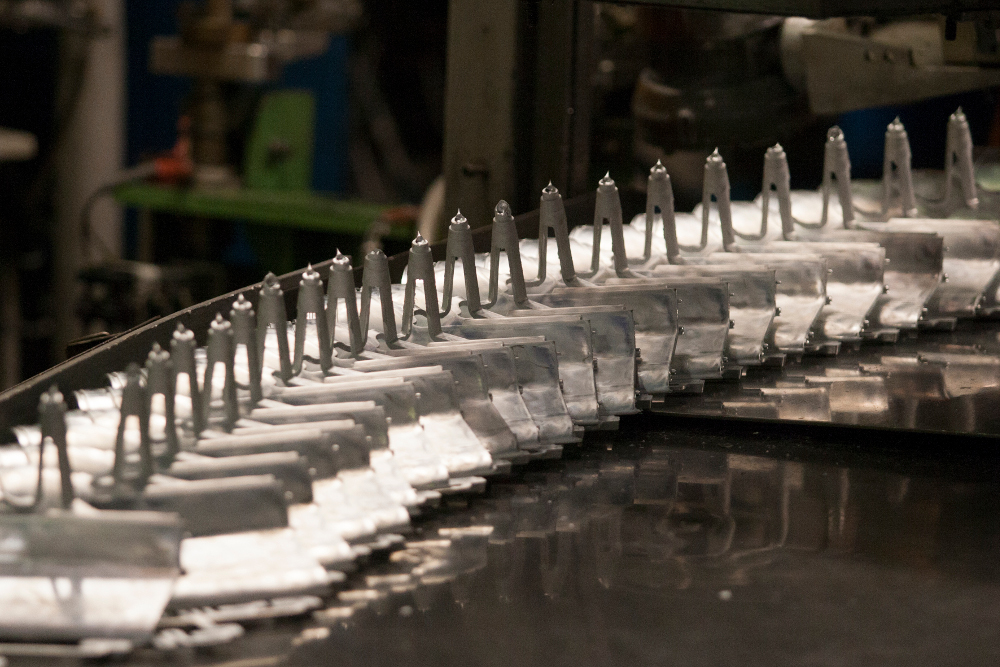

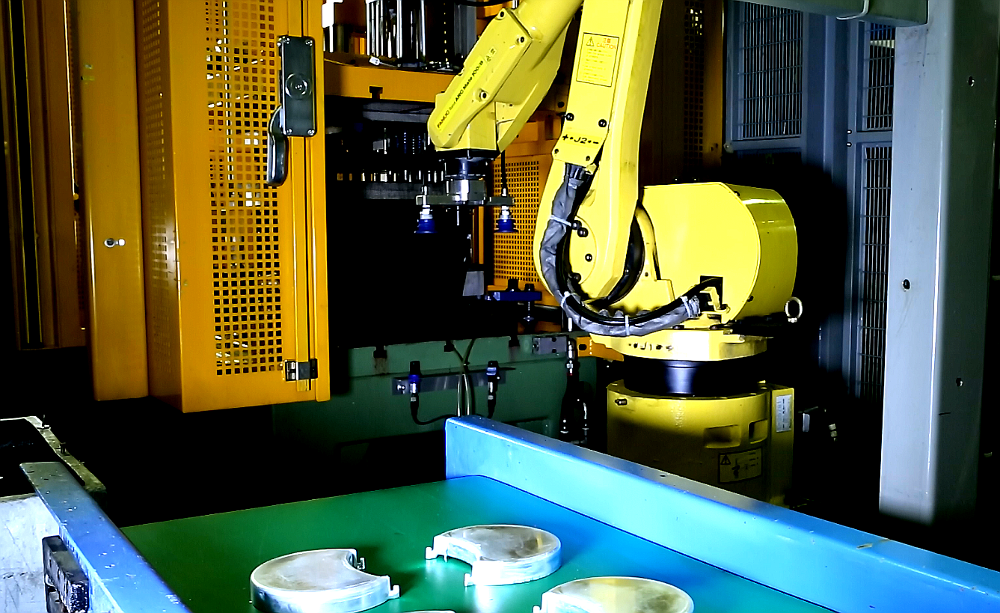

In this post we are going to examine a case study concerning a project for reducing manual operations through the introduction of automation, which has brought benefits to the whole production process.

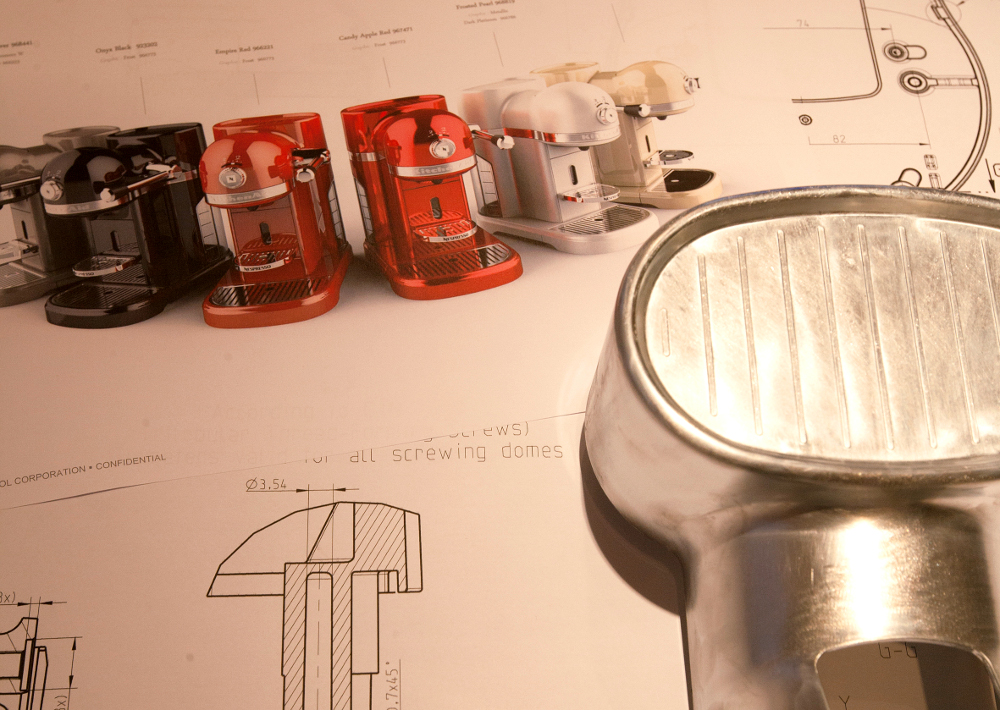

Zinc is a material that can be employed in several manufacturing sectors, including the branch of small appliances. The following post describes the main advantages of the use of zinc for the production of small appliances components, specifically of coffee machines components.

The term product design defines the process of designing a new product that has to be marketed in a specific business, taking into account not only its aesthetical characteristics but also its functions and its production cycle. Indeed, the product must meet the final user expectations while simultaneously be compliant with the production process.