Bruschi die casting BLOG. Stay on top of the Industry

As winner of numerous international awards, Bruschi Spa is known for its innovative approach in design and technology. We are glad to share our insights and experiences with the industry members.

Just like atmospheric environment, which is different for corrosivity depending on where people are located in the world, the same is for metal corrosion in automotive parts: for example in Sweden the automotive environment is quite aggressive because of humid climate and of the use of de-icing salts causing metals corrosion.

One of the main fields of application for zinc alloy products is surely the building sector. Depending on the position of the component and its visibility, various surface treatments are required to improve aesthetics and functionality.

Zinc die casting finishes are processes applied in order to modify surfaces of manufactured items, products or components with the purpose of reaching client requirements and improve functional and aesthetical quality of a product.

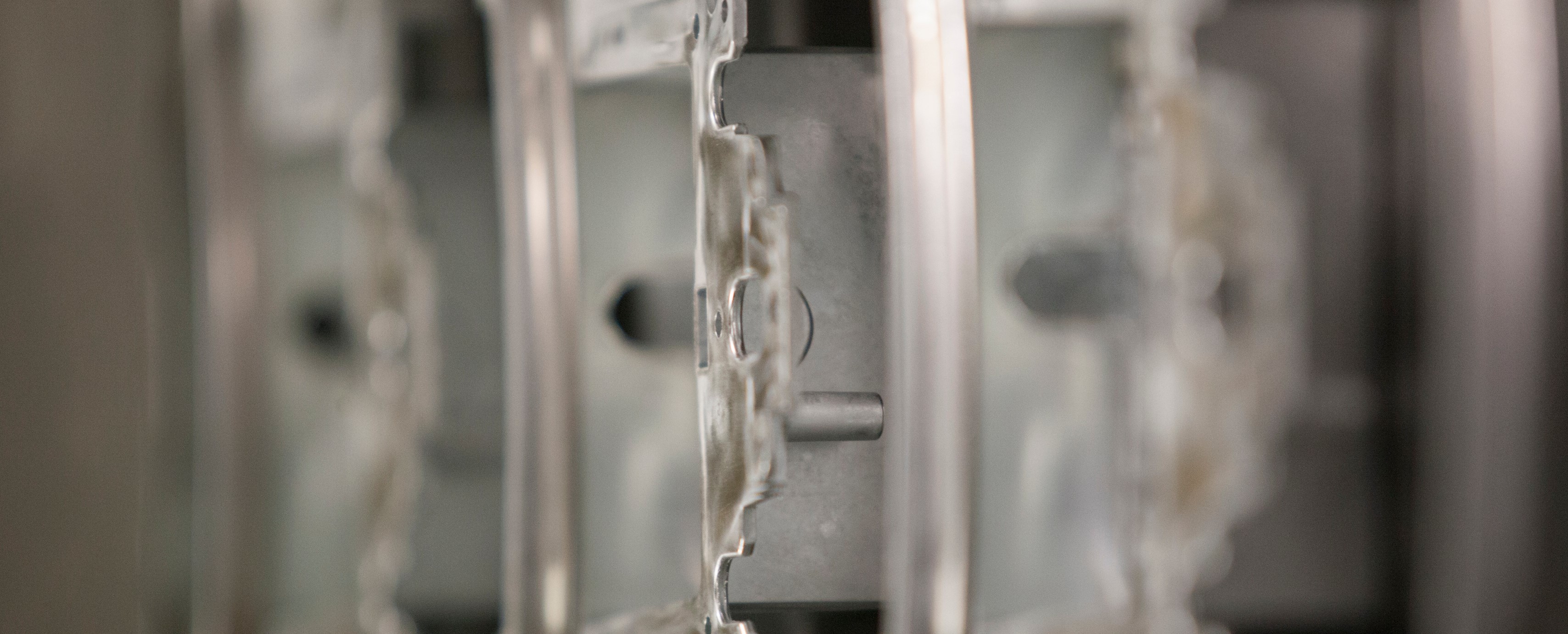

The main die casting defects which occur during die casting can be divided in categories related to different phases of production process: die casting, pre-finishing, machining operations and surface finishing. In particular in this article we are going to analyze defects related to the first category: die casting.

Black zinc is a zinc plating treatment which gives aesthetic and functional characteristics to products' surface. In this article we are going to deeply and technically analyze this treatment but, first of all, it could be useful to have an introduction on zinc plating main characteristics and which different types are most commonly used.

The automotive industry has requirements that are both functional and aesthetic when designing a component which should be produced by using die casting process. The main aspect a die caster will seek to ensure is oxidation prevention, therefore requirement on component is to extend resistance to atmospheric agents.

It may seem impossible but it is not! Reducing costs adding a die casting finish is really possible. The trick is just trusting your supplier and its expertise: collaboration with it in co-design terms. Starting a collaboration with suppliers can help clients to find a suitable solution to obtain the same requirements: with new solutions, but less costs.

Diecast finishes are every industrial processes applied to modify product or component surface in order to improve its aesthetic or technical quality. These processes are applied to improve or modify electrical conductivity, remove burrs and other flaws and for many other reasons. Furthermore, diecast finishes allow obtaining the desired aesthetic feature and coating durability.

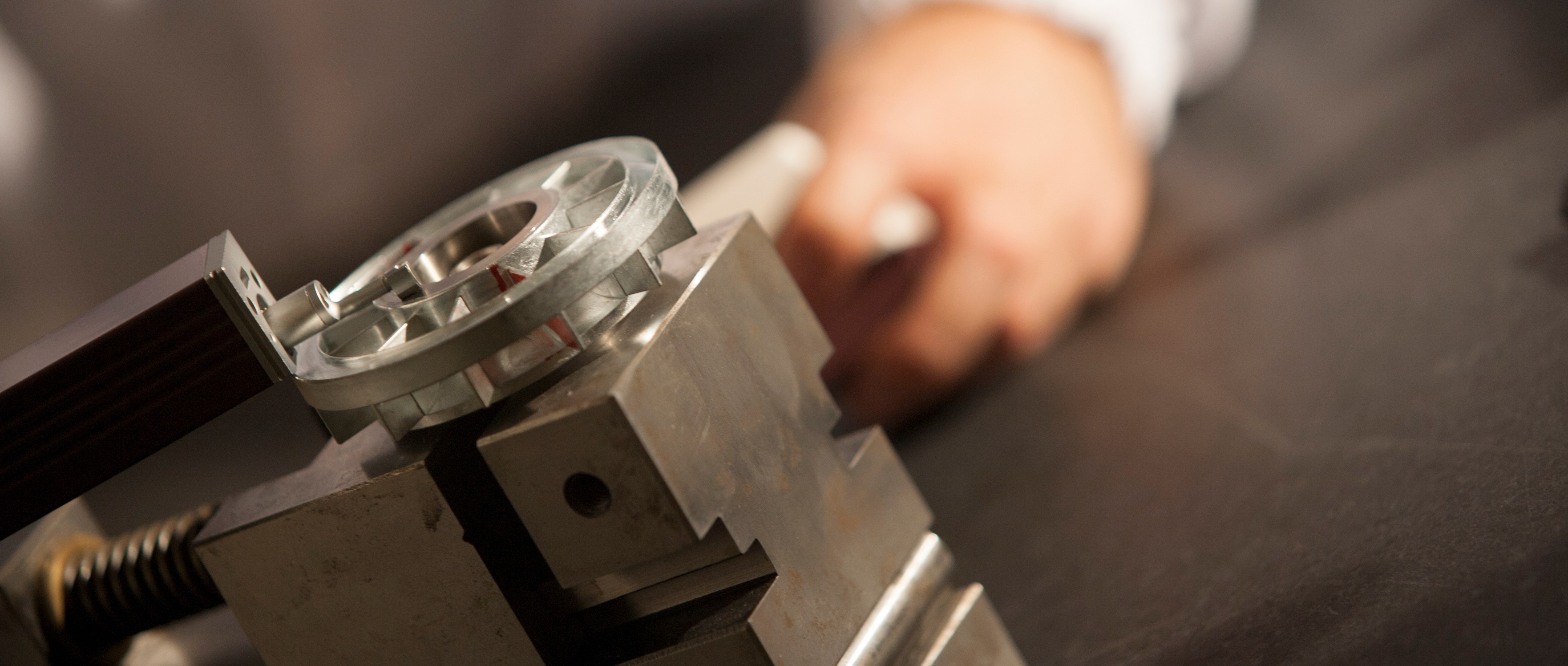

Die casting surface treatments are operations that lead to obtain a finished product starting from the casting aiming at increasing aesthetical and functional characteristics of a product or component. Can be either production cycle last phase or a step, where component surface is prepared for other following treatments.

In die casting, zinc die casting finishing process might improve the product appearance and performance. Zinc die casting parts can be submitted to different kinds of post treatments for many reasons, such as improving a product appearance, conferring resistance to chemicals, corrosion and wear, improving or modifying electrical conductivity and removing burrs and other flaws.