Bruschi die casting BLOG. Stay on top of the Industry

As winner of numerous international awards, Bruschi Spa is known for its innovative approach in design and technology. We are glad to share our insights and experiences with the industry members.

Industry 4.0 tries to gather every phase of production process into simulation. In particular in die casting engineering, simulation has to consider several points: productive plant, die casting tools, automation tools, cooling tools, secondary operation tools.

In order to apply a cost reduction in casting the designer should have a global view of the entire process. Casting process is composed of different phases that allow zamak becoming finished and packaged product: in this post we will examine the six stages of die casting process and analyze how and when it is possible to reduce costs.

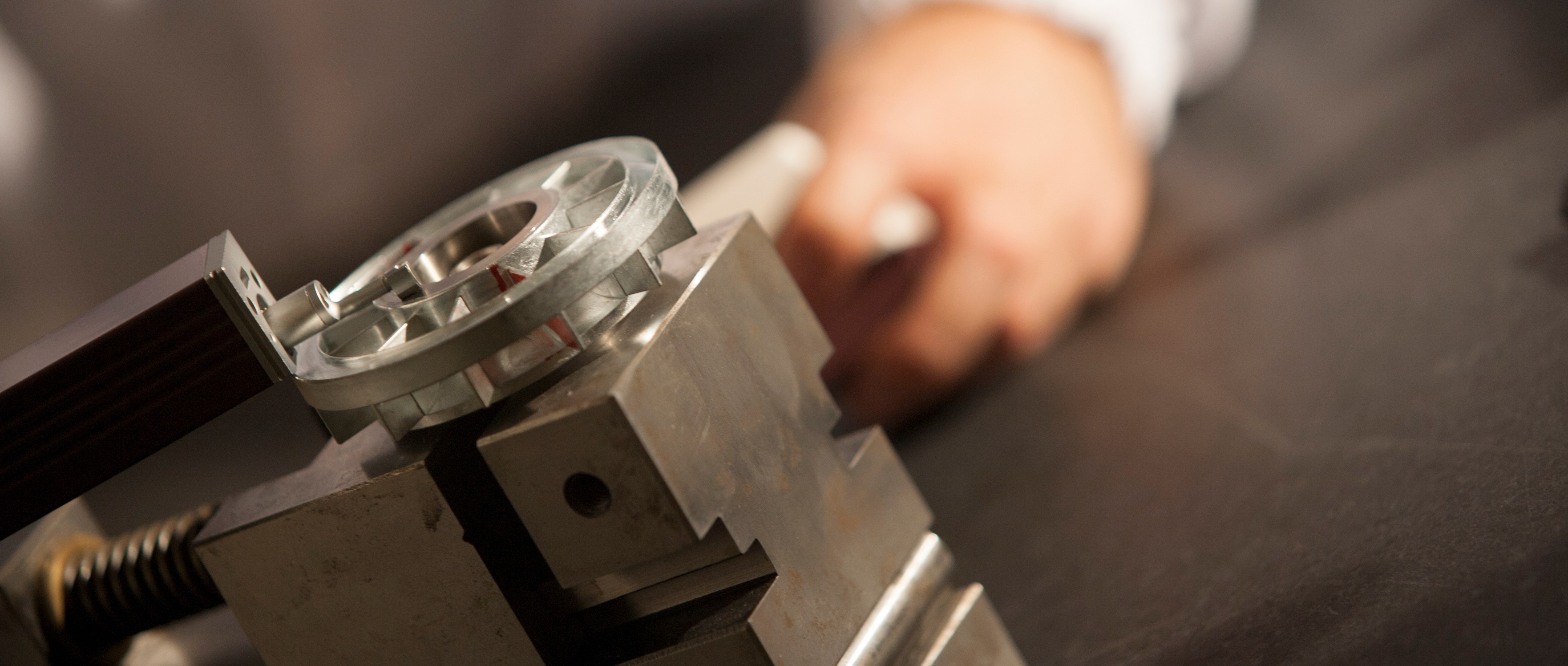

Among die casting services a supplier may offer to its customers, co-design is fundamental to realize a product with specific technical requirements. Co-design is the collaboration between the client and the die casting supplier, and it is fundamental to realize a product that has technical characteristics requested for its functionality and its aim and is at the same time in compliance to the process of die casting.

The most important element selecting the materials for the production and processes is trying to minimize costs of the product and its production. Producing, finishing, delivering and assembling costs depend on a wide range of factors. In this post we are going to understand in which areas companies can obtain costs savings.

A customer oriented company should focus on a co-design service that can help to cut costs. Manufacturing costs of products can be categorized into: raw materials, labor and process. In this regard product engineers are always trying to reduce production and material costs but also to maintain the quality of the product: value analysis and value engineering (VAVE) is really fundamental to reach this goal.

To predict shrinkage porosity and other defects, simulation is increasingly used nowadays, as these software require less development cost and time than experiments. Only some specific simulation programs, however, take into consideration the effect of back pressure in the cavity in die-casting. In this article we are going to discuss: what is shrinkage porosity, causes of the defect and how to avoid it with simulation.

Product design is an important part in die casting engineering which can be optimized adding a co-design process. Co-design activity is composed of three different phases: prrocess design, cost analysis and product design.

Zinc casting alloys provide a better combination of strength, toughness, rigidity, bearing, performance and economical castability than any other alloy possible. In fact their properties often exceed the ones of other alloys such as aluminium, magnesium, bronze, plastics and other cast irons. For its properties of strength and duration zinc is the perfect choice for saving time and money.

In Bruschi an important evolution of the customer service has given many concrete advantages for the company and its clients: in terms of cost saving, risks minimizing and a better logistic management.

Supply chain is the management of the flow of goods and services from the point of origin to the point of consumption: a cluster of activities done in order to meet customer’s requirements, to coordinate the suppliers, clients and the company itself. In this post we are going to describe how a well-structured supply chain can lead to costs saving.