All the posts for benefits

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

Zinc alloys are an excellent choice for creating and manufacturing appliance components. This blog post will explain why zinc alloys are widely used in this sector, highlighting their aesthetic, functional, environmental, and economic advantages.

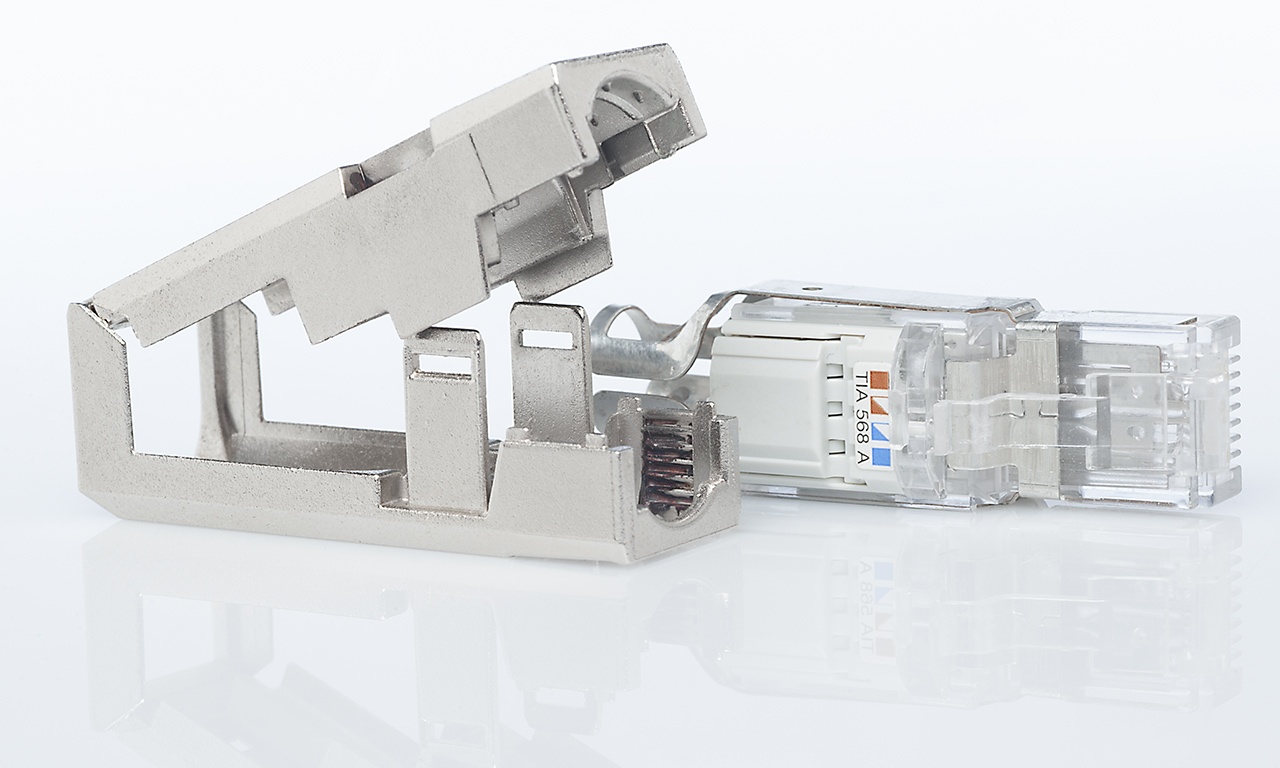

In this post we are going to briefly analyze the characteristics of zamak and to highlight its advantages in the production of components for electronic products. After that, we will review some components explaining how choosing zamak has made them more beneficial compared with similar products manufactured with other materials.

Thanks to their excellent mechanical and physical properties zinc alloys are a perfect material for die casting: they are indeed resistant, fluid, durable and rigid. But which are the best zinc alloys for hot chamber die casting? In this post we are going to analyze the different characteristics of zinc alloys for hot chamber die casting in order to define the best choice on the basis of the features that the final product requires.

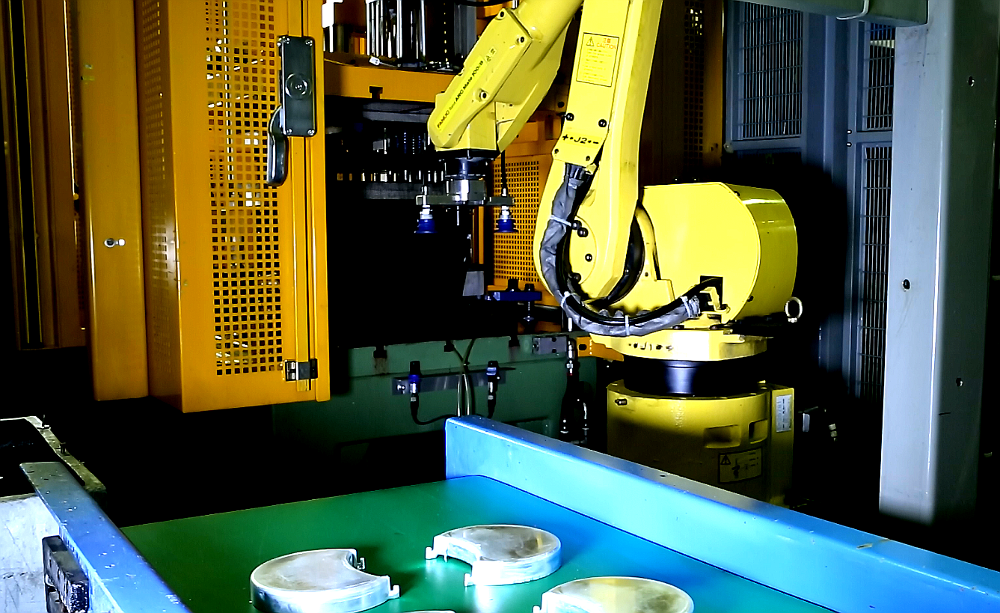

In this post we are going to examine a case study concerning a project for reducing manual operations through the introduction of automation, which has brought benefits to the whole production process.