All the posts for defects-reduction

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

In this post, we will address the main problems concerning the possible casting defects that could arise in the die-casting process and which would compromise the success of subsequent surface treatment. This treatment, which can be a galvanic or a painting, can be carried out for aesthetic and functional reasons.

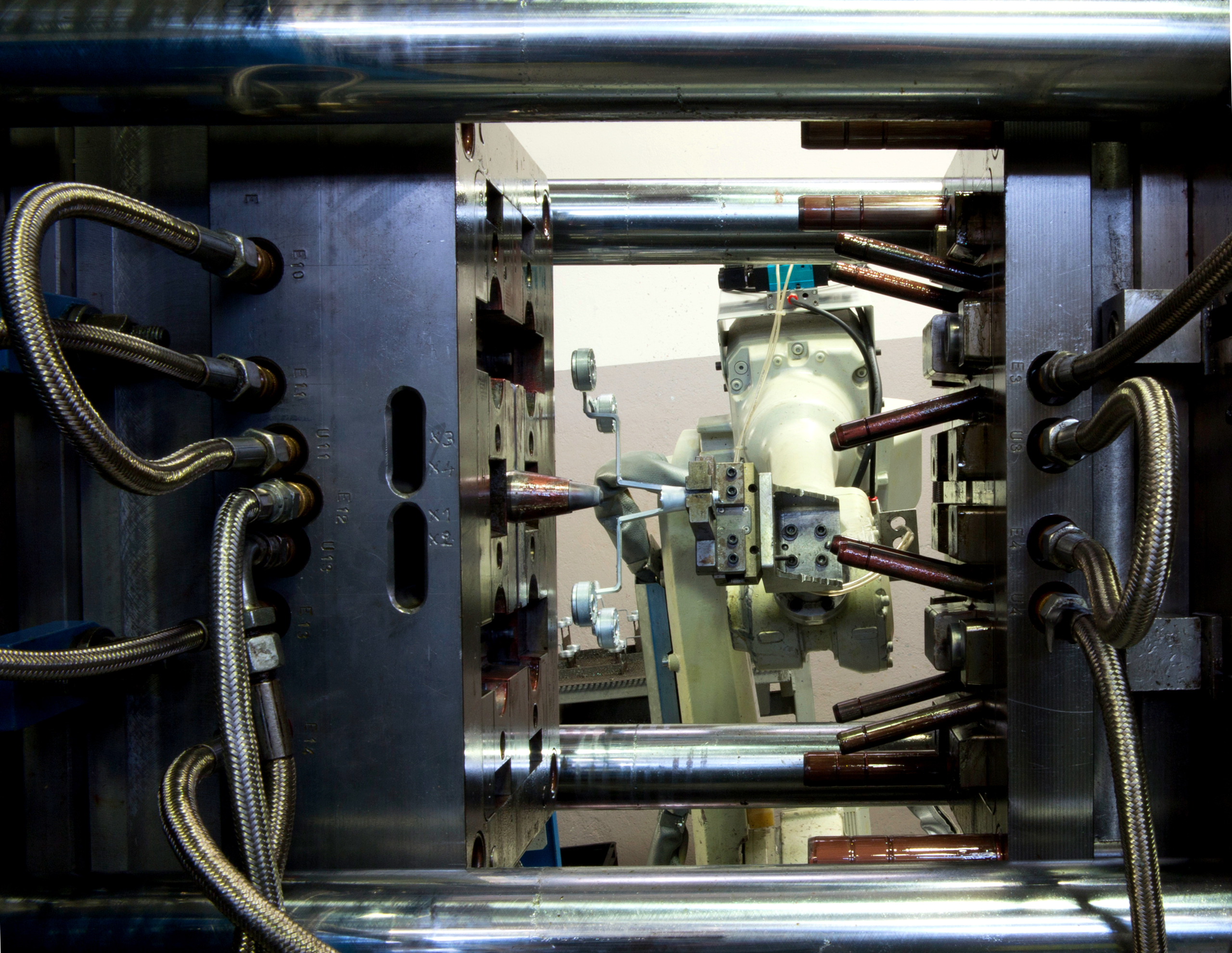

This post deals with the fundamentals of die casting machines and their role in the whole die casting process. Moreover, the post gives an outlook on the sector's future perspectives.

In this post, focused on the metrology laboratory, we will describe the devices employed to measure and test zinc alloy die casts intended for different market sectors.

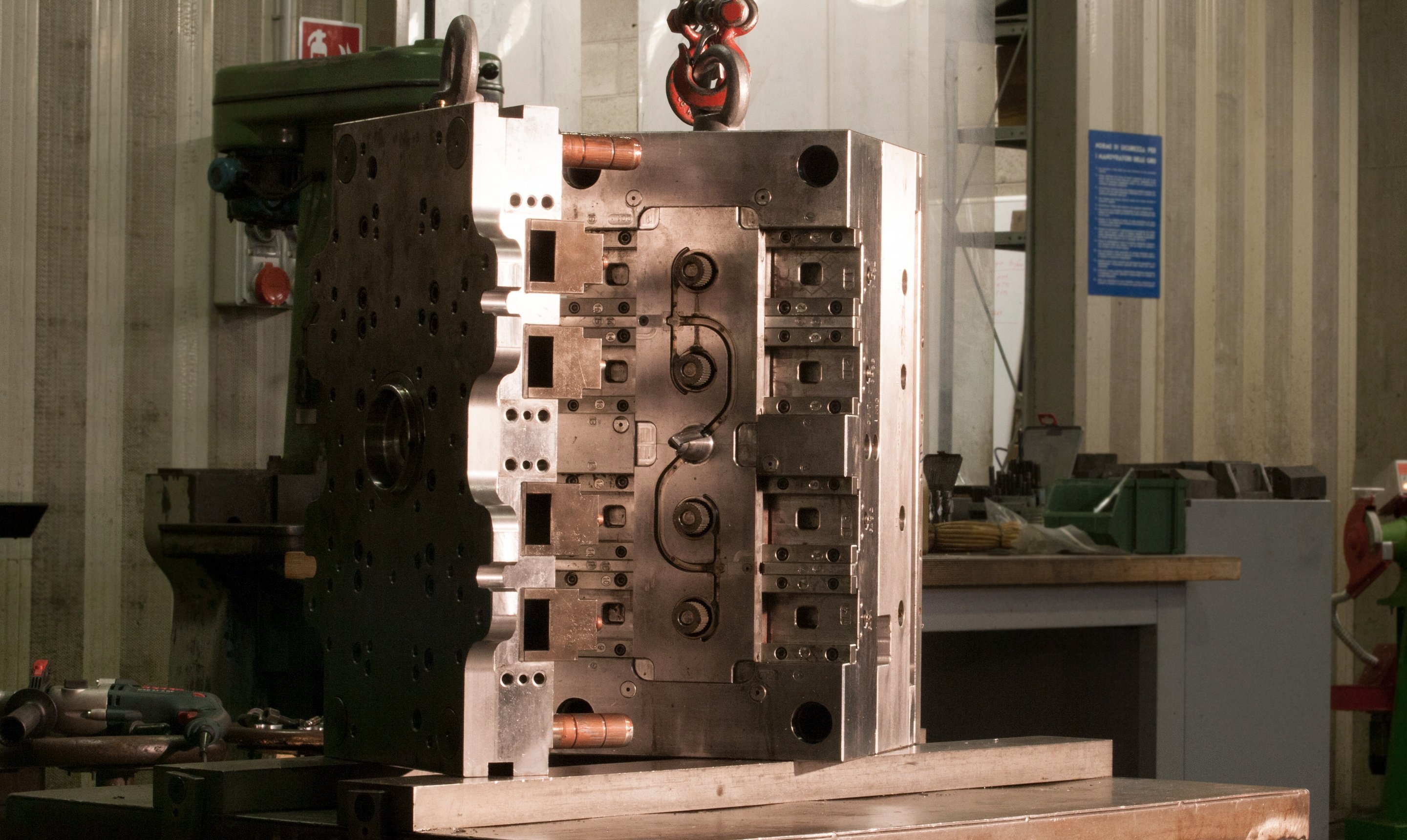

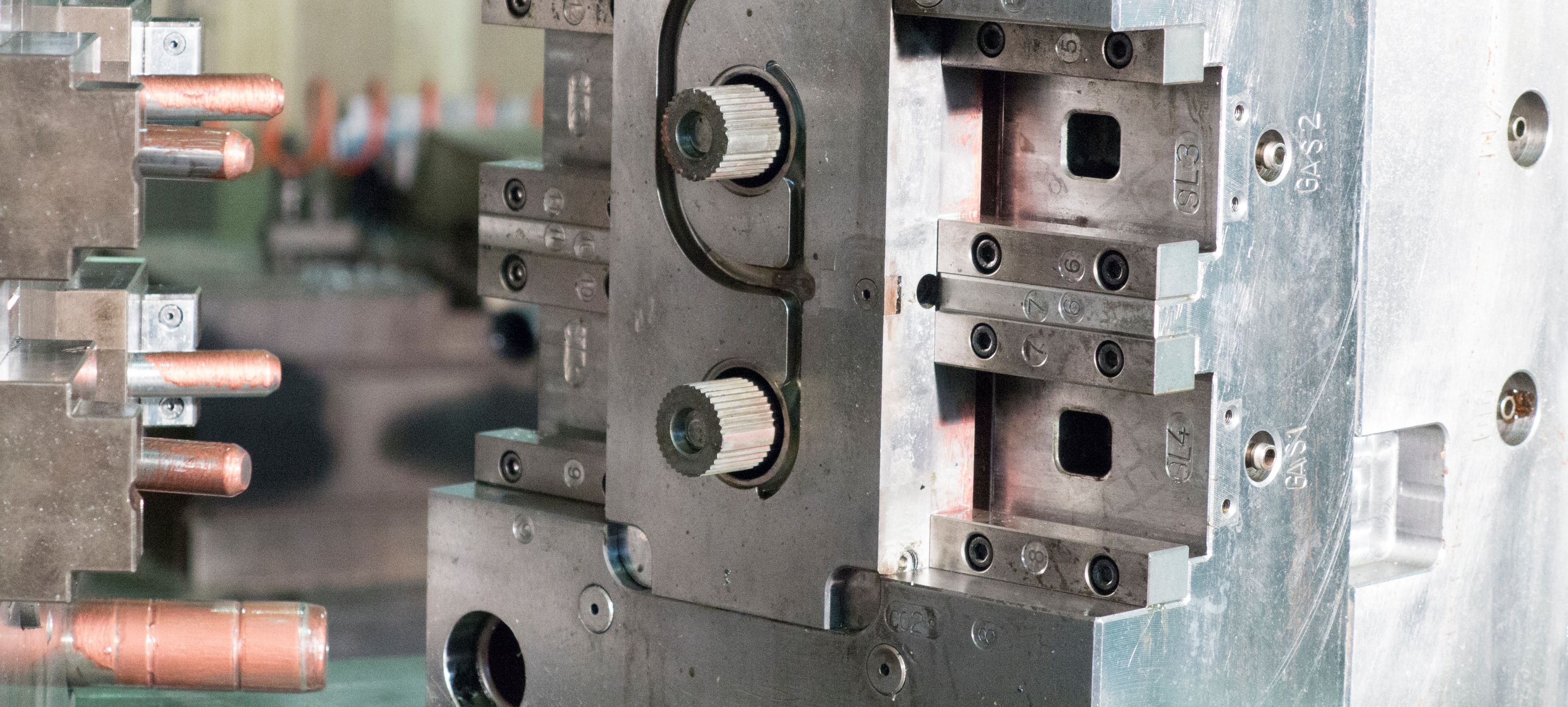

In this post we are going to analyze a case study that explains how to reduce casting defects through mold design. Due to mold wear condition components started to show superficial defects: Bruschi engineers have thus introduced improvements in order to reduce casting defects.

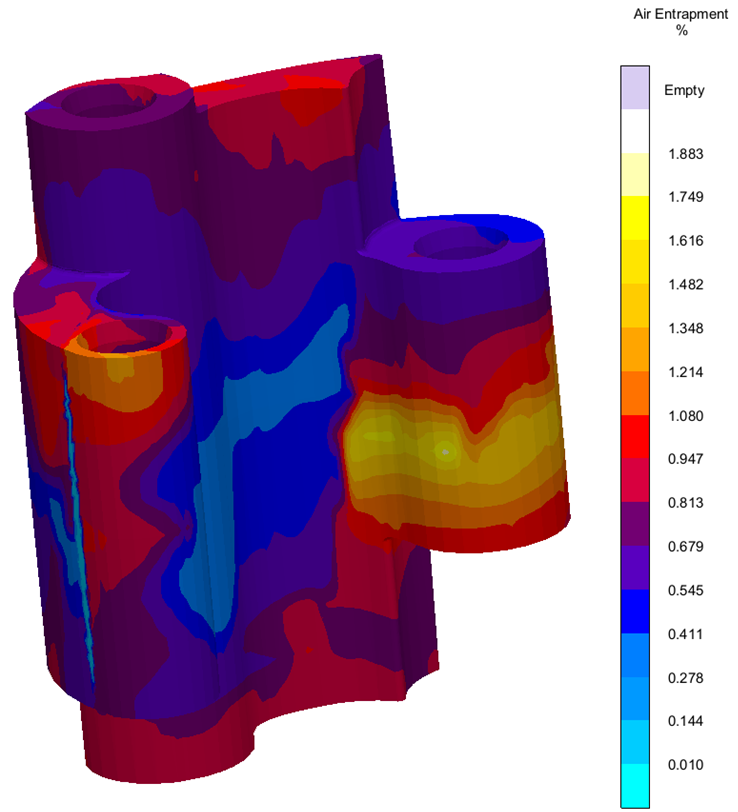

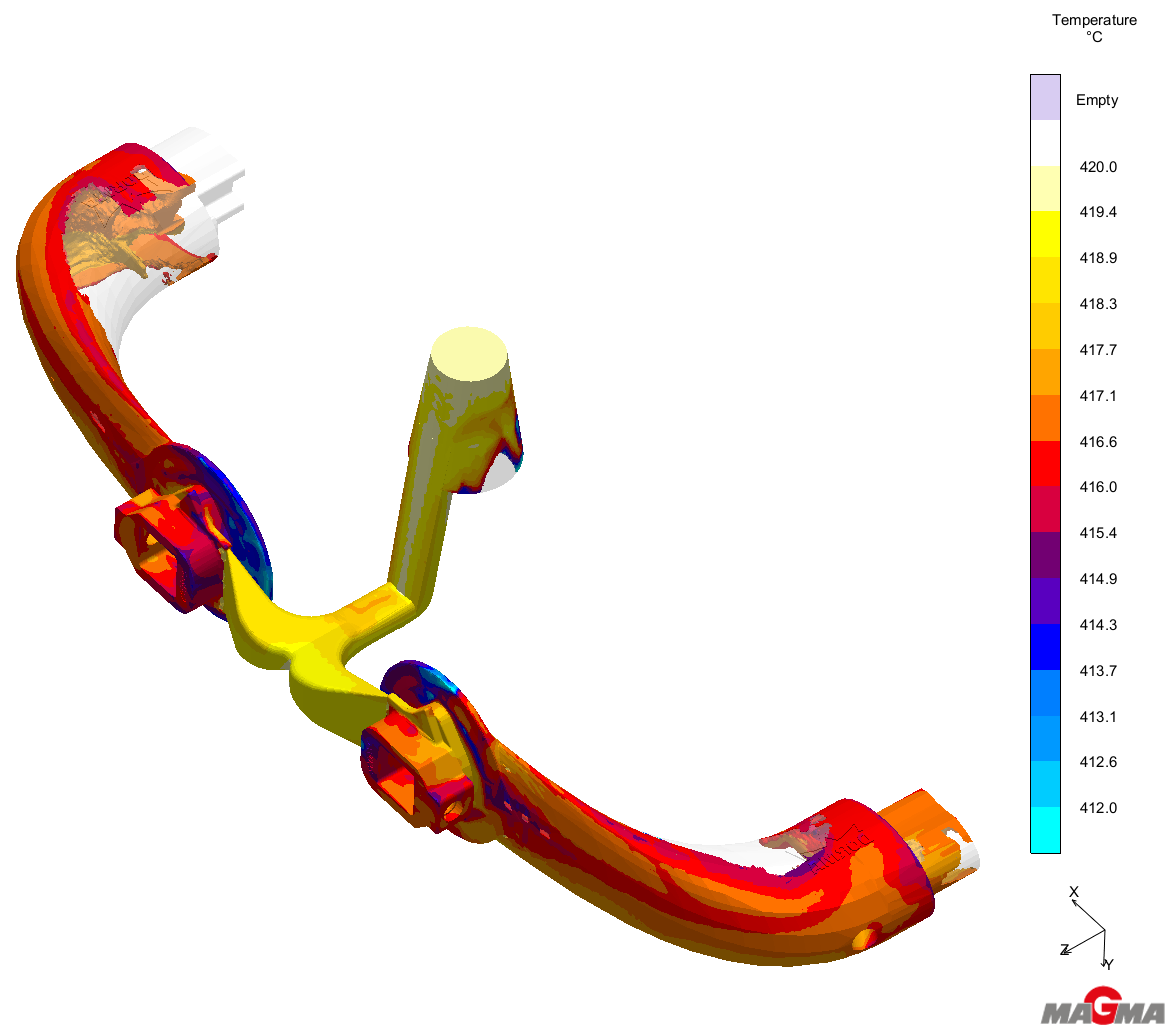

In this post we are going to explore a case study dedicated to the improvement of mechanical characteristics, by reducing shrinkage porosity in a component for building sector. This post is part of a series in which we explain the importance of simulation for HPDC (High Pressure Die Casting) through the presentation of real life cases.

In this series of posts, we are going to explain the importance of simulation for HPDC (High Pressure Die Casting) through the presentation of different case studies, in which simulation played a crucial role.

In this post we are going to analyze some surface defects in die casting linked to errors in the painting process of zinc die cast products.

In this post we are going to list the most common defects in zinc die casting surface treatments and explain how to prevent them. We are going to analyze the following defects: blisters, pitting, burnings, nodules and flaking.

In this post we are going to discuss some of the most common defects in die casting linked to mold maintenance, and how they can be fixed by the maintenance department.

In this post we are going to describe in detail the relation between mold maintenance department and foundry: how the inclusion of maintenance department and tooling department in the production area can bring actual economic advantages and time saving.