All the posts for die-casting-finishing

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

The versatility of zinc alloys can be tested in some sectors more than in others. A sector that offers great creative and design freedom is household appliances: in fact Zamak components for household appliances contribute to make the entire object unique, exclusive and immediately recognizable.

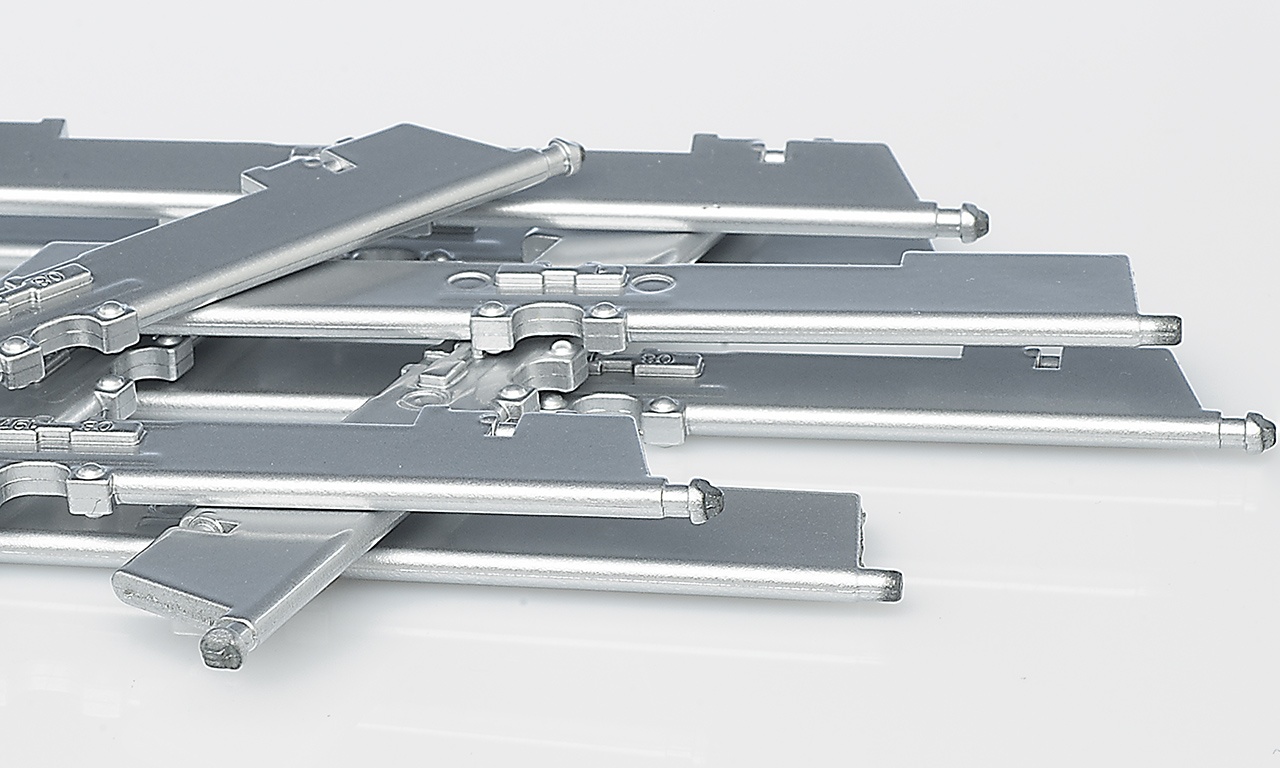

Thanks to their excellent mechanical and physical properties zinc alloys are a perfect material for die casting: they are indeed resistant, fluid, durable and rigid. But which are the best zinc alloys for hot chamber die casting? In this post we are going to analyze the different characteristics of zinc alloys for hot chamber die casting in order to define the best choice on the basis of the features that the final product requires.

Zinc is a material that can be employed in several manufacturing sectors, including the branch of small appliances. The following post describes the main advantages of the use of zinc for the production of small appliances components, specifically of coffee machines components.

The term product design defines the process of designing a new product that has to be marketed in a specific business, taking into account not only its aesthetical characteristics but also its functions and its production cycle. Indeed, the product must meet the final user expectations while simultaneously be compliant with the production process.

In this post we are going to explore a case study dedicated to surface aesthetical quality in automotive. This post is part of a series in which we explain the importance of simulation for HPDC (High Pressure Die Casting) through the presentation of real life cases.

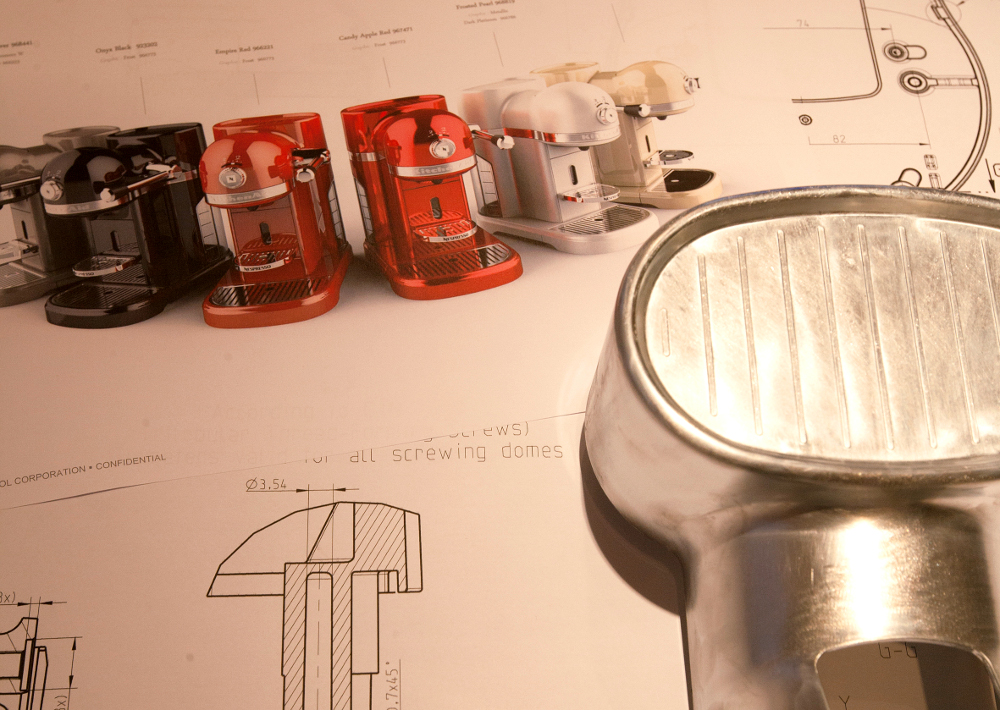

In this post we are going to describe the business philosophy of functional beauty. Starting from this philosophy, Bruschi created Nespresso KitchenAid Artisan 5KES0503, a design coffee machine that led the company to the victory of the prestigious European Zinc Die Casting Competition for design in 2016.

In this post we are going to list and define the most common surface treatments for zinc die casting and their effects, and we are going to present three case studies in which the application of a specific treatment helped in improving the overall performance of the component.

In this post we are going to describe what is meant with surface finishing and we will explain why it is important to take them in consideration from the designing phase of a component, giving some advice for the optimization of the most critical points.

In this post we are going to analyze some surface defects in die casting linked to errors in the painting process of zinc die cast products.

In this post we are going to list the most common defects in zinc die casting surface treatments and explain how to prevent them. We are going to analyze the following defects: blisters, pitting, burnings, nodules and flaking.