All the posts for vave

Posts by Topic

- Die Casting simulation (35)

- Co-design (26)

- Cost reduction (23)

- die casting finishing (18)

- Defects reduction (16)

- high pressure die casting (16)

- die casting process (15)

- VAVE (13)

- die casting (12)

- Zinc (11)

- Zinc benefits (10)

- casting process (10)

- die casting engineering (10)

- optimization (10)

- Innovation (9)

- automotive (8)

- casting (8)

- ZAMAK (7)

- product design (6)

- quality (6)

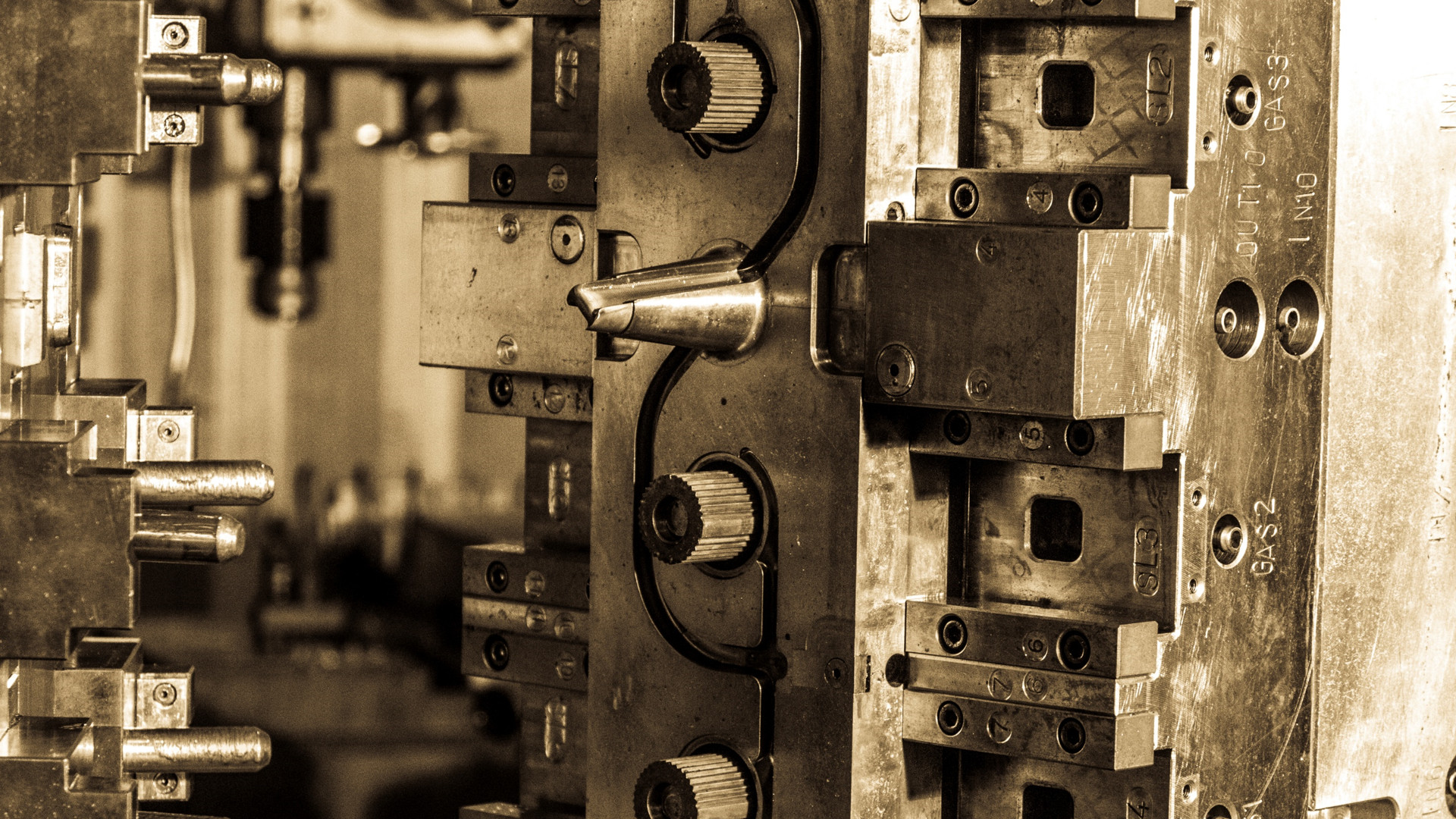

- Mould Design (5)

- Scrap reduction (5)

- automation (5)

- saving (5)

- Mold (4)

- benefits (4)

- die casting machines (4)

- hot chamber die casting (4)

- industry (4)

- supply chain (4)

- zinc alloys (4)

- Commodity (3)

- coffee market (3)

- mold maintenance (3)

- process improvement (3)

- small appliances (3)

- technology (3)

- thin wall thickness (3)

- Shrinkage porosity (2)

- costs saving (2)

- customer service (2)

- cycle time (2)

- electronic products (2)

- improvement (2)

- metrology (2)

- mold design (2)

- process analysis (2)

- production (2)

- production process (2)

- recycling (2)

- sustainability (2)

- white goods (2)

- zinc life cycle (2)

- DFM (1)

- Electromechanical systems (1)

- HPDC (1)

- Lighting components (1)

- Press (1)

- SME (1)

- Textile (1)

- Textile Machineries (1)

- Zinc alloy actuators (1)

- actuators (1)

- chrome plating (1)

- environment (1)

- industrial machinery (1)

- industrialization (1)

- lead time (1)

- machines (1)

- painting (1)

- quality control (1)

- surface treatment (1)

- tier 2 automotive supplier (1)

- vacuum valve (1)

- zinc alloys for doors and windows (1)

Cost reduction in zinc die casting is an activity that shall be executed without affecting the quality and functionality of the component that is produced. All the activities that aim to increase productivity, to diminish scrap rate and to simplify productive processes, as well as the choices of materials and processing, are cost reduction strategies.

In this post we are going to discuss the advantages of involving suppliers in procurement strategy, and how they can impact the final result of a VA/VE analysis.

In this post we are going to explain what Value Analysis / Value Engineering is, starting from its history up to why it is so important for manufacturers today.

The main die casting defects which occur during die casting can be divided in categories related to different phases of production process: die casting, pre-finishing, machining operations and surface finishing. In particular in this article we are going to analyze defects related to the first category: die casting.

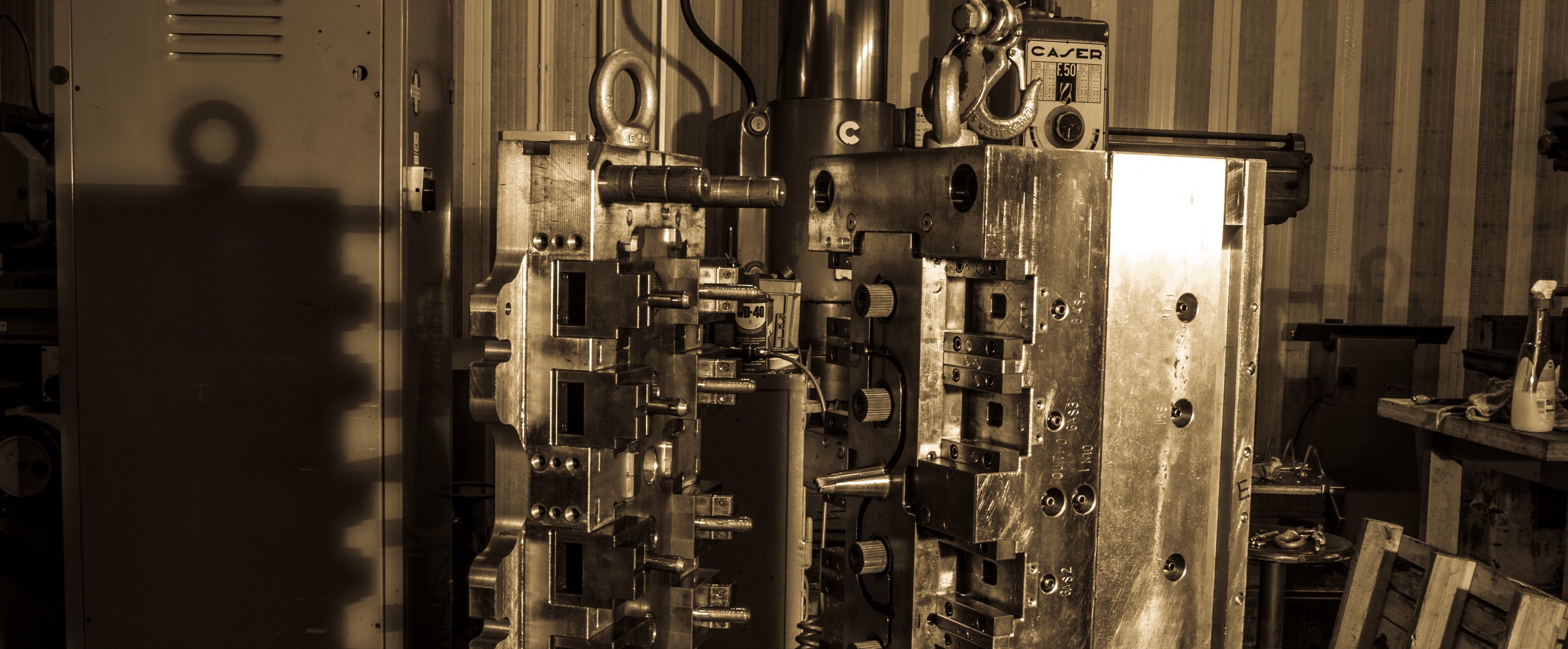

Choosing the perfect zinc die caster is an important issue: this choice could determine the good or bad outcome of a product. In order to reach clients’ expectations is important to consider every production aspect: to organize it in the best way possible it is important to analyze the entire production process.

In this post we are going to see how the involvement of zinc die caster supplier can lead to improvements in the diecast quality and from a cost point of view, thanks to the following activities: co-design, simulation and the choice of zinc.

The main benefits of using Zinc alloys are accuracy, machinability, thin wall capability, castability, dimensional stability, and joining feasibility. Zamak die casters should help their customers reduce manufacturing costs, which in that industry can be divided into three main fields: raw materials, labour and process.

Industry 4.0 tries to gather every phase of production process into simulation. In particular in die casting engineering, simulation has to consider several points: productive plant, die casting tools, automation tools, cooling tools, secondary operation tools.

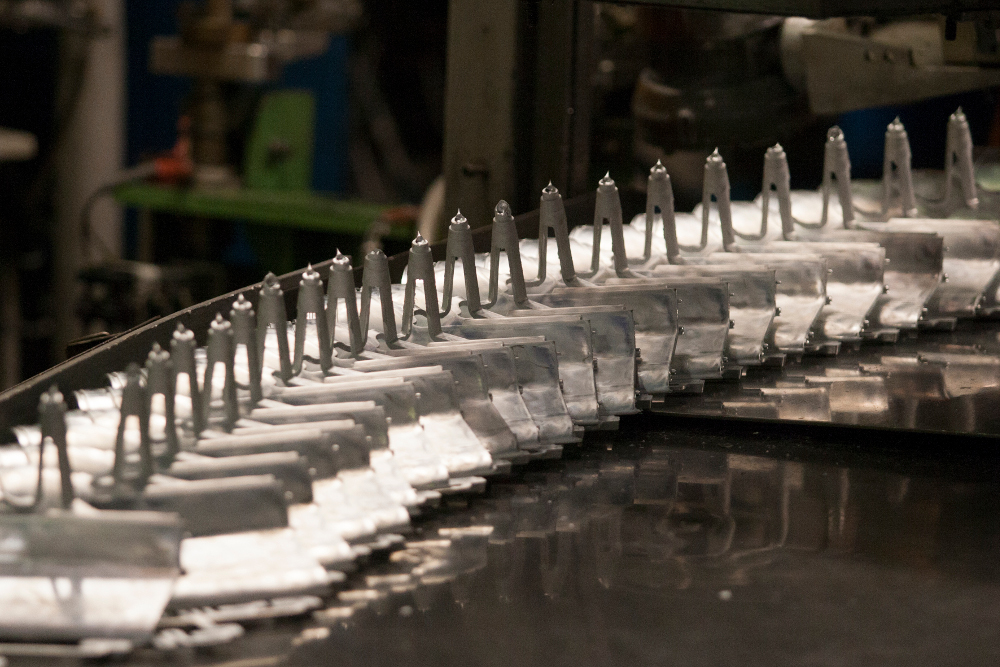

In order to apply a cost reduction in casting the designer should have a global view of the entire process. Casting process is composed of different phases that allow zamak becoming finished and packaged product: in this post we will examine the six stages of die casting process and analyze how and when it is possible to reduce costs.

The most important element selecting the materials for the production and processes is trying to minimize costs of the product and its production. Producing, finishing, delivering and assembling costs depend on a wide range of factors. In this post we are going to understand in which areas companies can obtain costs savings.