All the posts for zinc

Posts by Topic

- News (43)

- Event (37)

- Bruschi (27)

- Innovation (14)

- Zinc (10)

- industry (9)

- Award (6)

- die casting (6)

- IZA (5)

- best italian smes (5)

- sustainability (5)

- North America Plant (4)

- Training (4)

- Zinc benefits (4)

- automotive (4)

- health (4)

- Aluminium (3)

- Certification (3)

- Commodity (3)

- Open Factory (3)

- Press (3)

- coffee market (3)

- production (3)

- COVID-19 (2)

- Co-design (2)

- Cost reduction (2)

- Die Casting simulation (2)

- Excellent Company (2)

- SMETA 4-Pillars (2)

- benefits (2)

- die casting engineering (2)

- digitalization (2)

- environment (2)

- events (2)

- industrial machinery (2)

- process improvement (2)

- recycling (2)

- safety (2)

- small appliances (2)

- technology (2)

- universities (2)

- Acquisition (1)

- Defects reduction (1)

- Earth Day (1)

- Huf (1)

- Leonardo da Vinci (1)

- Sapre (1)

- casting process (1)

- champions 2019 (1)

- costs saving (1)

- cycle time (1)

- die casting machines (1)

- die casting process (1)

- digital marketing (1)

- improvement (1)

- machines (1)

- product design (1)

- production process (1)

- quality (1)

- sales (1)

- saving (1)

- sustainability policy (1)

- thermal deburring (1)

- video (1)

- white goods (1)

- zinc alloys (1)

- zinc life cycle (1)

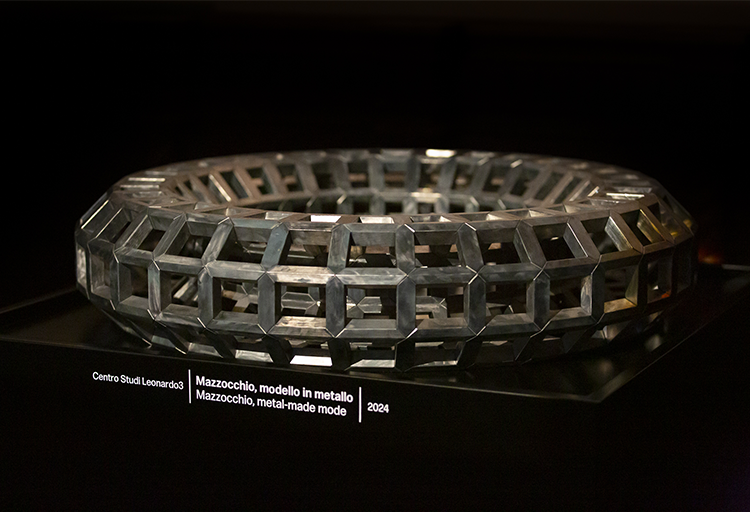

Bruschi, commissioned by the Leonardo3 Museum - The World of Leonardo in Milan, has brought to life an extraordinary work inspired by Leonardo da Vinci’s famous drawing: the Mazzocchio. This intricate structure, made up of 32 octagonal sections and 512 individual pieces, was unveiled to the public on November 14, 2024, during an exclusive preview at the milanese museum.

We are pleased to announce that, effective December 1st, 2024, Bruschi will finalize its merger with Sapre, marking an important milestone in its growth strategy.

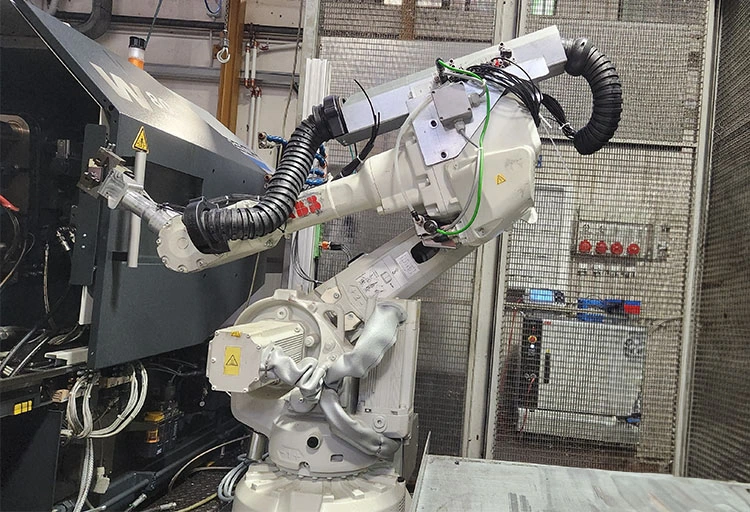

A heartfelt thank you to everyone who joined our webinar, “Comparing Materials in Die Casting: Advantages and Applications of Zamak and Aluminum.” It was inspiring to share insights on the properties and applications of zamak and aluminum, exploring the strengths of each material in the die casting field.

In 2023, Bruschi successfully completed an important innovation challenge in the development of zinc die-cast products, requested by a German company in the automotive sector, the mass production of a component of very small dimensions that respected the stringent weight constraint imposed by the customer.

Industrial zinc life cycle is based on the principles of circular economy and it contributes in different ways to the protection of our Earth. In this post we are going to describe how zinc, thanks to its countless properties, positively impacts on our planet.

White goods manufacturers are facing new challenges due to customers’ growing awareness on sustainability and recycling: taking into account these needs and defining the right practices can lead to sales improvement.

Zinc proves to be a reliable ally for a circular economy model, since not only does it maximize the lifespan of the product without altering their recyclability, but it’s in itself an highly recyclable material. This is highly compatible with circular economy goals, which aims to reduce new resource exploitation through use of recycling.

Zinc is a chemical element that is the 27th most abundant element in the Earth’s crust. Naturally occurs in air, water, soil and biosphere, in fact it is contained in many rocks and minerals, in plants and animals. Zinc is essential to all lives.

Bruschi, expert in zinc die casting field and supplier for many important automotive manufacturers, suggests to use zinc instead of other materials to obtain a better product: from its aesthetic side to its functional one.

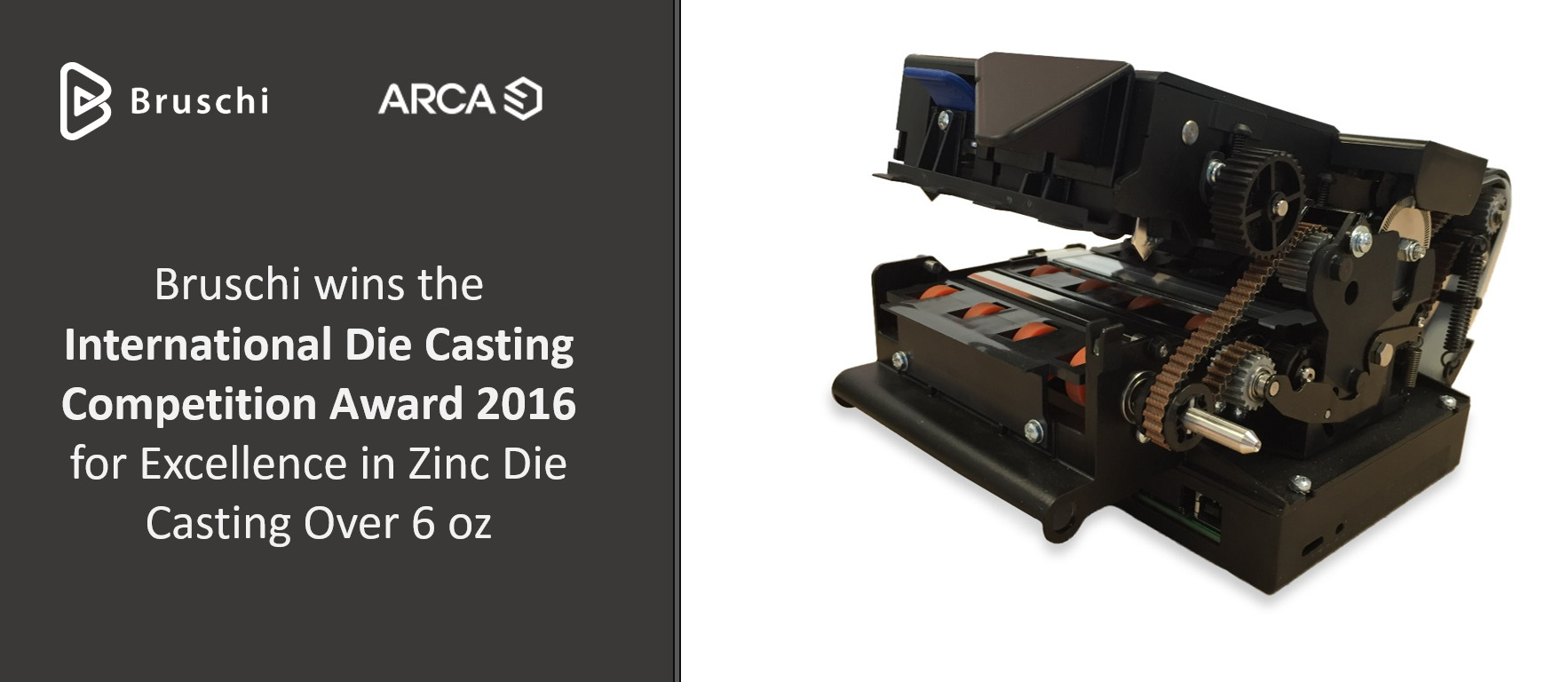

Bruschi wins the prestigious NADCA award during the 2016 International Die Casting Competition. This award represents another important recognition of Bruschi’s innovative approach and strive for excellence. Another win for Bruschi after the prestigious European Zinc Die Casting award.