- Home

- Services

Zinc die casting services

We offer an integrated vertical approach to zinc die casting, starting from the idea to create the most functional products for our customers

“Our integrated vertical approach to die casting is composed not only of mass production but also of services: our versatility and innovation enables us to take up new challenges everyday. We do not fear complexity: complexity is a key factor in Bruschi, it is capable of bringing new incentives and new energy. Complexity, competition and challenges belongs to the history of Bruschi: to the past, present and future.”

Paolo Rastelli, CEO of Bruschi

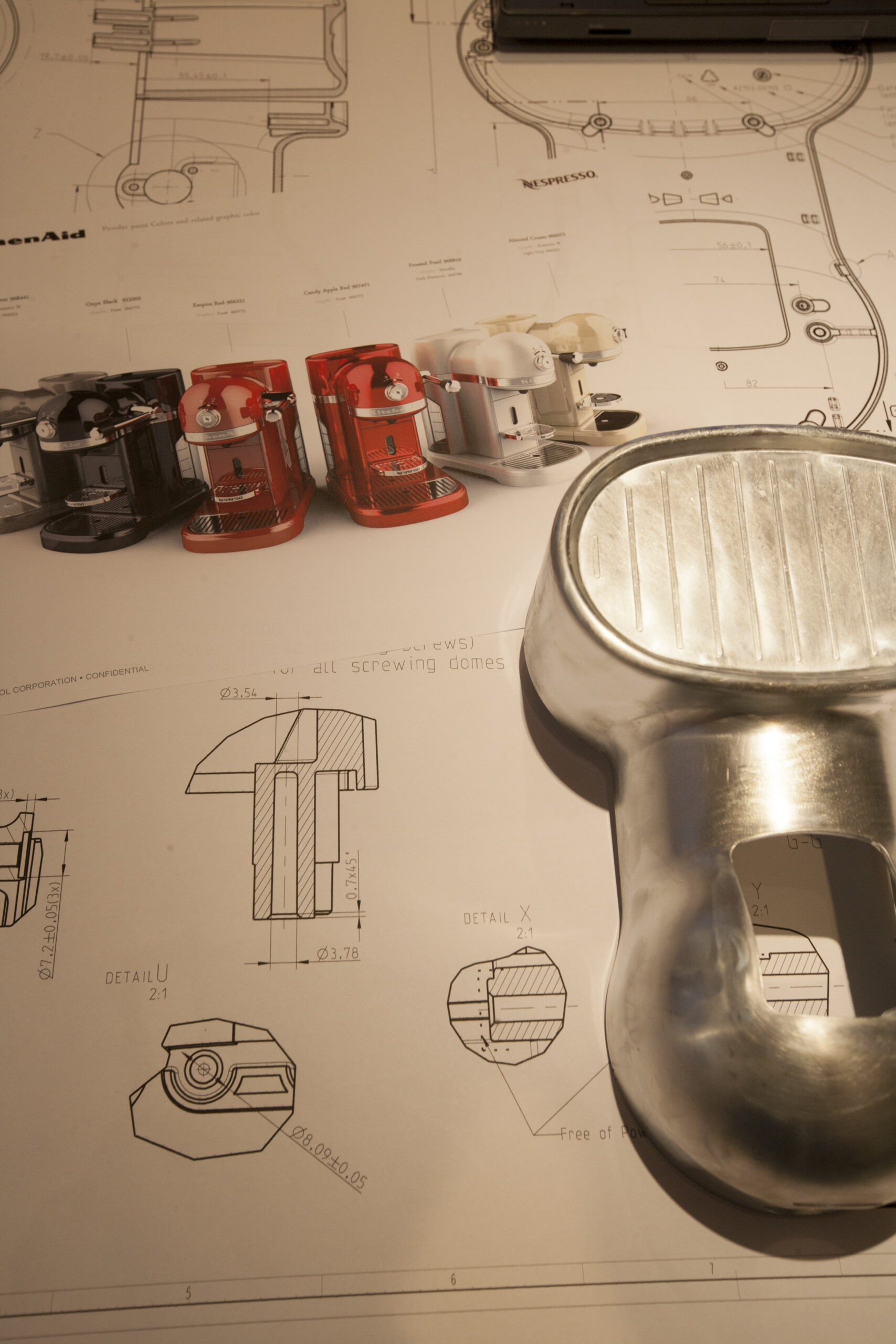

Co-design

The co-design service, undertook together with the customer, allows to improve the design or functionality of the product. Taking into account the entire production process, Bruschi team analyses and simulates the process to optimize the performance of the product and the process, reducing time and costs.

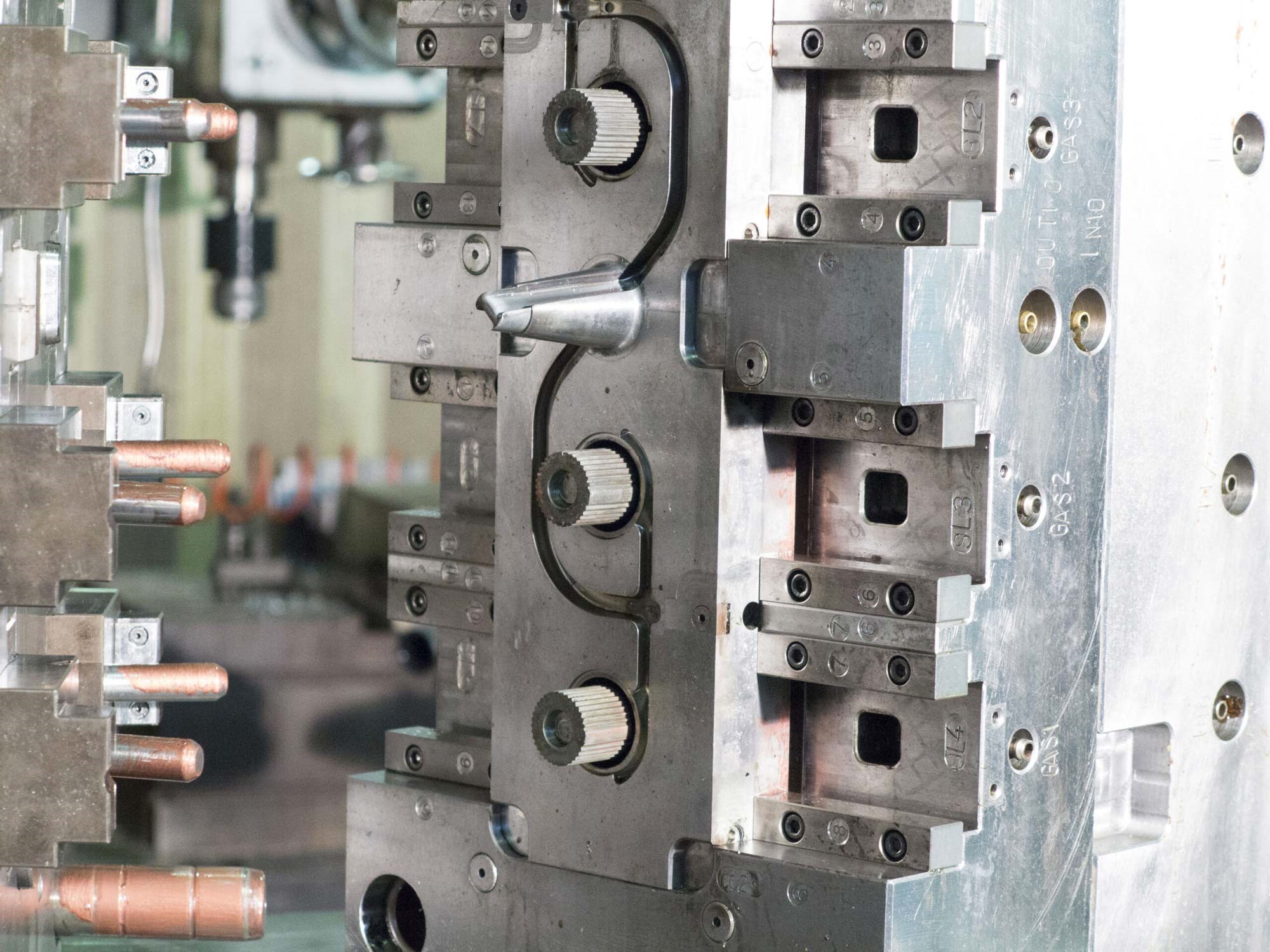

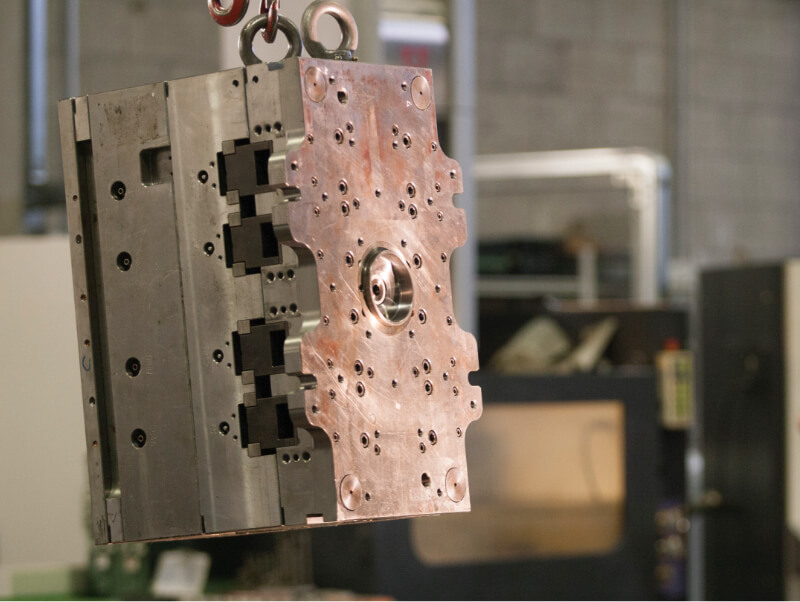

Tool design and construction

The experience gained in the field of zinc alloys die casting, the use of special simulation software and the co-desing activities undertaken together with the customer allow Bruschi to design and build high performance molds characterized by innovative technical solutions, such as vacuum valve, a technology developed for the first time in Bruschi in 1983.

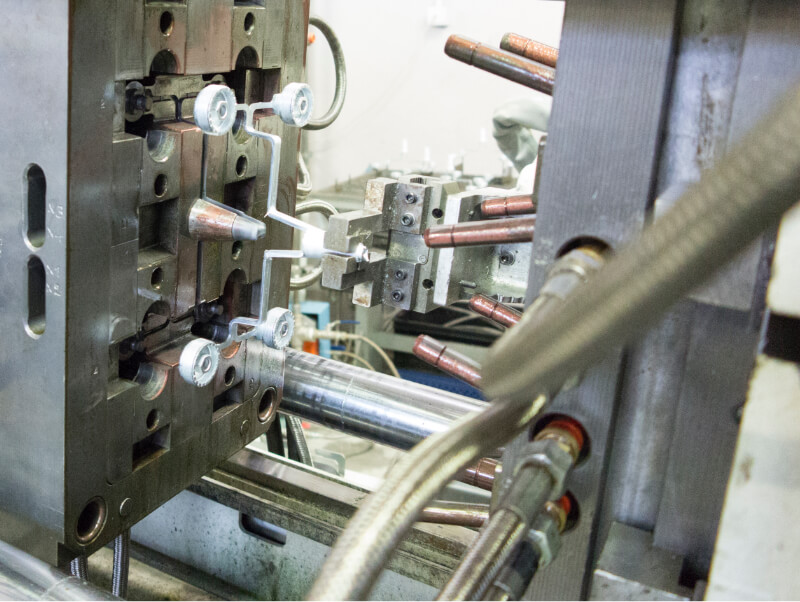

Die casting

Bruschi, with its own hot chamber die casting machines, processes 6500 tons of zinc every year to produce more than 110 million components. The knowledge and mastery of die-casting technology allow the Bruschi team to create products capable of satisfying every customer need, characterized by a high degree of detail, thin walls thickness and excellent surface quality.

Mechanical Operations

Mechanical operations are an integral part of the production process of Zamak die castings. The special automation and robotics projects created in Bruschi significantly reduce production times by guaranteeing customers components that do not require further processing.

Painting & Chroming

Zinc alloys components allow designers a great freedom: the smooth, compact and defect free surface of the die castings make them suitable for undergoing a wide variety of surface treatments. Whether it is a liquid or powder painting, chroming or glazing, aesthetic or protective treatments, Bruschi’s team will guide the customer in choosing the most suitable treatment and process for the project.

AESI

Thanks to its AESI department, Automation Engineering & System Integration, Bruschi can guarantee its customers the ability to develop new machines for specific functions related to mass production processes. Technologies and skills in the sectors of Robotics, Machine Vision Systems, Pneumatics, Dosing Systems, Coding and Induction Heating Systems allow AESI to satisfy the most detailed needs of each project of all its customers in the world.

Assembling

With its own integrated vertical approach to die casting, Bruschi oversees every phase of the production process: from the Zamak ingot to the shipment of the product to the customer. Assembly is an integral part of the process and Bruschi develops and designs robotic and automatic systems to reduce cycle time and deliver finished products to its customers worldwide.