Multiple industries.

We bring you excellence in zinc and aluminum die casting.

Multiple industries.

We bring you excellence in zinc and aluminum die casting.

Zinc and aluminum: for over 75 years, Bruschi has been shaping even the most complex ideas through zinc and aluminum die casting. With experience, innovation, and flexibility, the company delivers tailor-made components for the most demanding industries.

We analyze every phase of the process to reduce waste and maximize efficiency, ensuring the best quality-price ratio.

We work methodically and quickly to transform ideas into concrete solutions in the shortest possible time, without sacrificing quality.

High quality

Zinc and aluminum: for over 75 years, Bruschi has been shaping even the most complex ideas through zinc and aluminum die casting. With experience, innovation, and flexibility, the company delivers tailor-made components for the most demanding industries.

Our optimized processes and in-house capabilities allow us to reduce production costs without compromising on quality.

High quality

Certified processes, precision technologies, and strict quality control ensure consistently high standards in every product we deliver.

Between Italy and United States

products per year

products per year

6500 Ton.

Zinc per year

What Bruschi can do

The range of Bruschi solutions: creativity and reliability rooted in Made in Italy

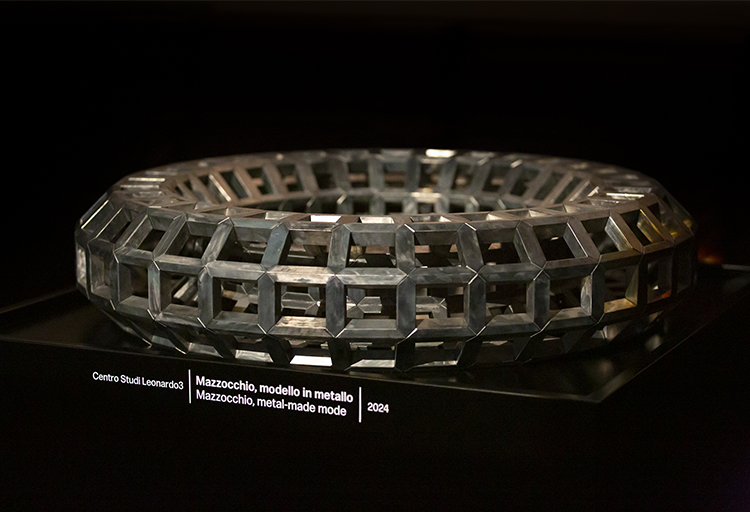

The versatility of zinc and aluminum alloys and hot chamber die casting technology allow us to obtain components intended for various application sectors and capable of responding to different types of requirements: aesthetic, technical or functional. The components produced in Bruschi are part of everyday life, we address global markets by offering targeted solutions that can be adapted to each production sector.

Zinc and aluminum components used in interiors, mechanical parts, and safety systems.

Our approach

We offer a vertically integrated approach to zinc and aluminum die casting, starting from the idea, to create the most functional products for our customers.

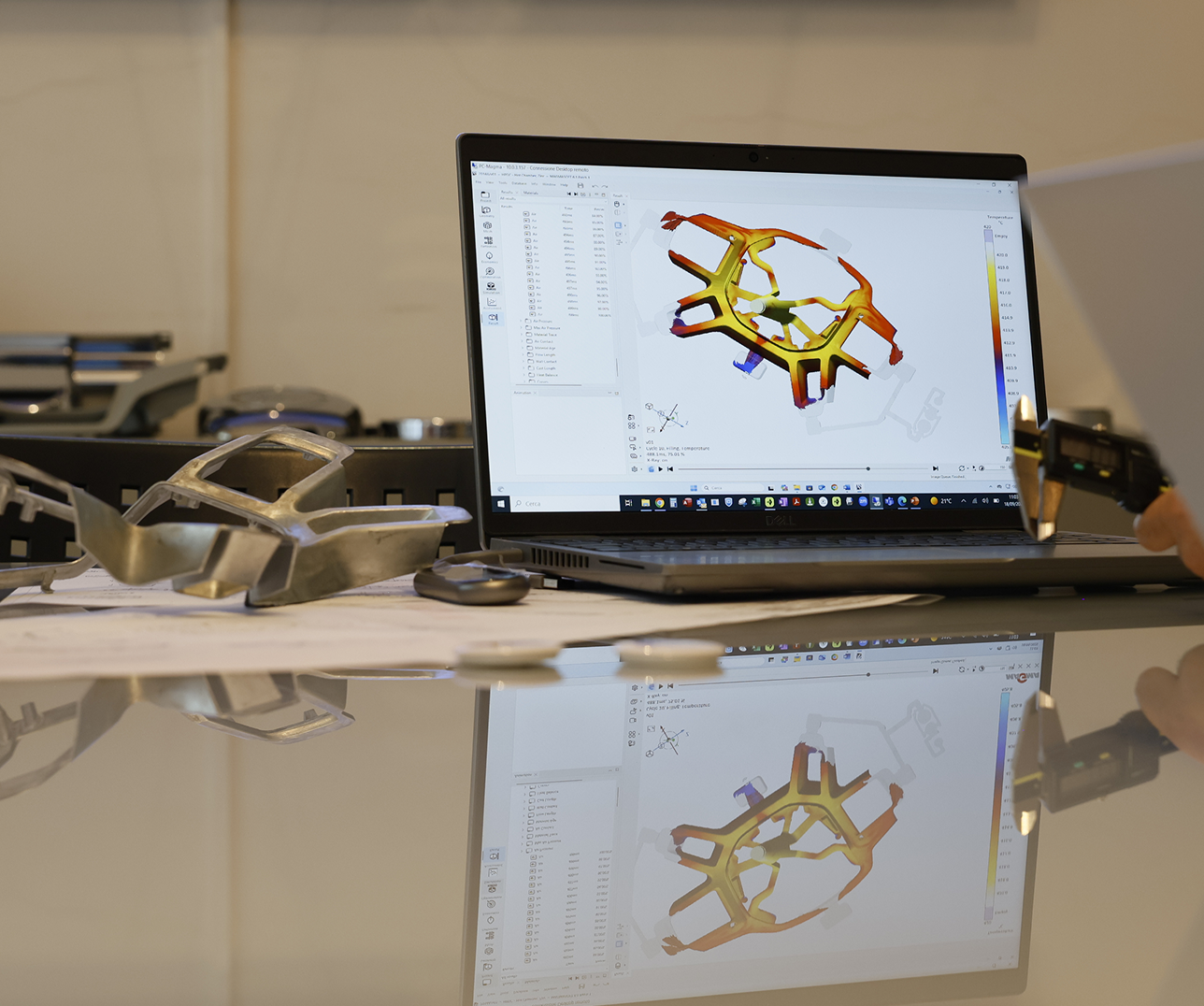

01. Co-Desing

Our co-design service, developed in close collaboration with the customer, improves product design and functionality. By analyzing the entire production process, our team performs simulations that enhance both performance and efficiency—saving time and reducing costs.

02. Tool design and construction

With extensive experience in zinc and aluminum die casting, advanced simulation software, and close co-design with clients, Bruschi develops high-performance molds. These include innovative solutions like the vacuum valve—a technology first pioneered at Bruschi in 1983.

03. Die casting

Bruschi processes 6,500 tons of zinc and 2,000 tons of aluminum per year, producing over 110 million components using hot-chamber die-casting machines. Our deep knowledge of this technology enables us to manufacture parts with high detail, thin walls, and excellent surface quality—fully tailored to customer needs.

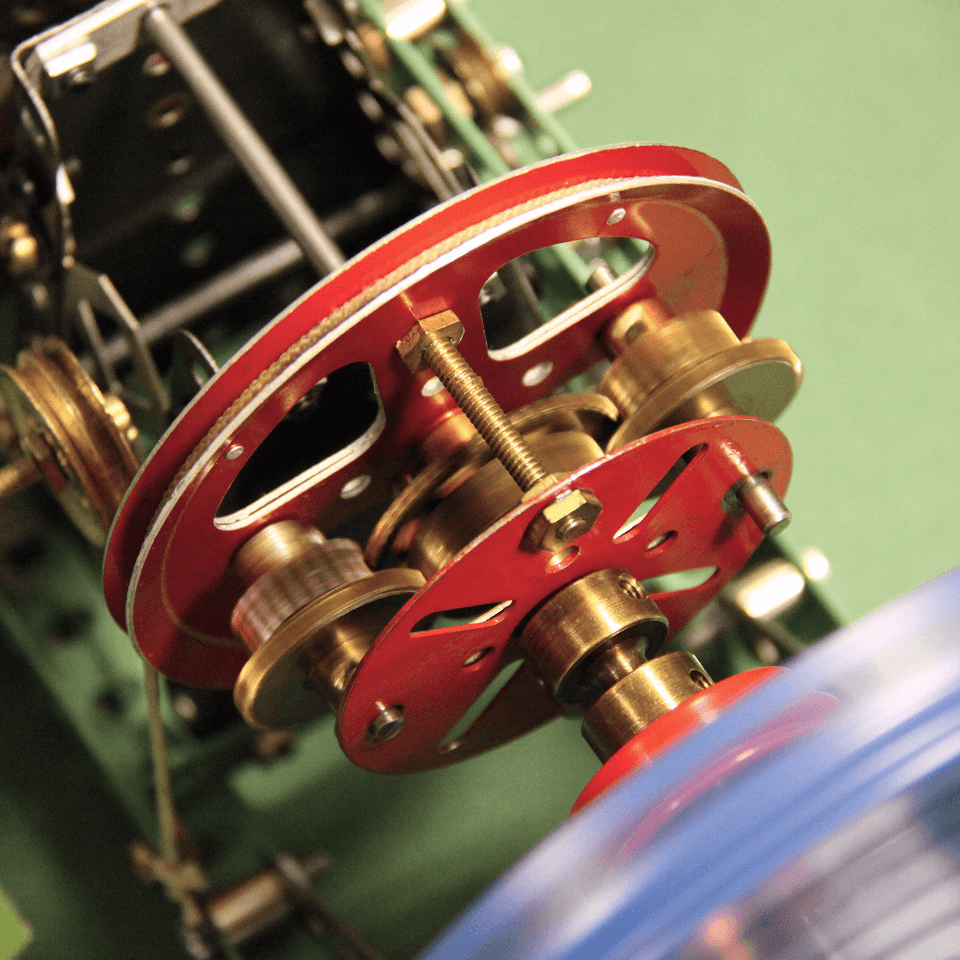

04. Mechanical Operations

Mechanical processes are an essential part of zinc and aluminum die-casting production. At Bruschi, custom automation and robotics projects significantly reduce production time, delivering ready-to-use components with no need for additional processing.

05. Painting & Chroming

Zinc and aluminum components offer great freedom in surface finishing. Their smooth, compact, defect-free surface makes them ideal for a wide range of treatments: liquid and powder coating, enameling, chroming, and more. Bruschi supports each client in selecting the best treatment for their project—whether functional or aesthetic.

06. AESI

Through our AESI division, Bruschi develops dedicated machines for specific mass production needs. With expertise in robotics, vision systems, pneumatics, dosing systems, coding, and induction heating, AESI meets even the most detailed technical requirements of projects worldwide.

07. Assembling

Bruschi manages every stage of the production process, from zinc and aluminum ingot to final delivery. Assembly is fully integrated into this process. We design and develop robotic and automated systems to reduce cycle time and provide finished, ready-to-ship products to customers around the globe.

Our History

Specialists in zama and aluminum molding since 1948

2023

Diversification

2020

International expansion

1996

Bruschi wins the first Nadca Award

1983

Vacuum valve

1980

Innovation

1964

Bruschi starts producing die-cast parts

1950/60

Growth

1948

Foundation

Our foundries operate according to the highest industry standards, as demonstrated by the quality certifications we have obtained. A constant commitment to ensuring reliability, safety, and precision at every stage of the production process.

Bruschi Journal

Stay updated with the latest trends in die casting, industry insights, and company events. Discover what’s shaping the future of zinc and aluminum foundry.